Inside the Absorption thermodynamic cycle

The GAHP absorption heat pump is a thermodynamic equipment suitable for transferring heat from low-temperature thermal sources to heating subsystems, raising the thermal level of the energy drawn.The refrigeration circuit of GAHP is derived from the GAX (Gas Absorption heat eXchanger) cycle. Compared with the classical refrigeration cycle of electric machines derived from the theoretical Carnot cycle, the system adopted in absorption differs by introducing the generation and absorption phases instead of compression. Downstream of the generation follows a condensation and evaporation at the end of which is added the absorption of the refrigerant fluid into the absorption fluid with strong heat development. The generation phase in fact consists of the evaporation separation of ammonia from water by the heat input of a flame, and is preceded by a series of pre-heating heat exchanges of the solution entering the generator. The absorption phase consists of an exothermic chemical reaction due to the chemical and physical characteristics of the two compounds used and the properties of the process governing their mixture.

Thus, the special feature of the cycle used in absorption machines is that it relies on excellent thermal energy development within the cycle itself due to the absorption reaction between the refrigerant and the absorbent. This feature makes it possible to reduce the energy requirements of the machine, reducing fuel consumption and making the efficiency of the machine little affected by the temperature of the renewable source of energy (air, water or soil).

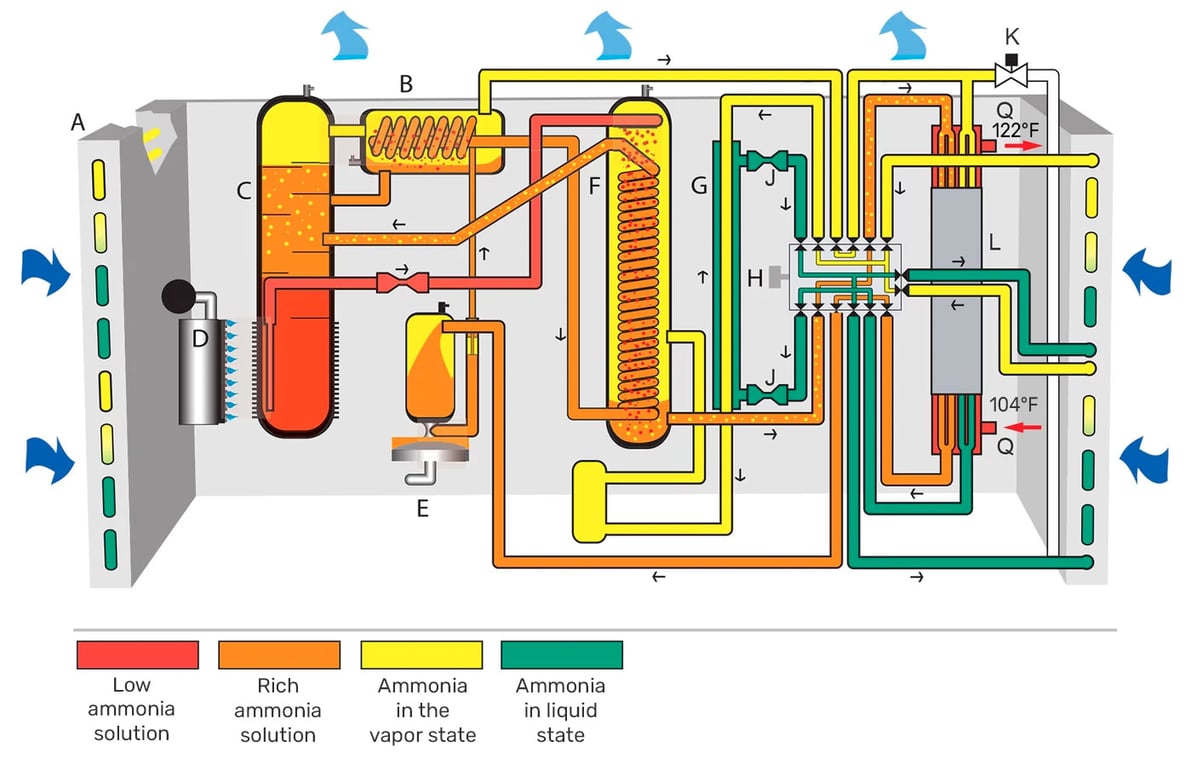

For a detailed description of the thermodynamic cycle, it is appropriate to refer to the hermetic circuit of a real machine shown in the figure, referring to a Reversible Gas Absorption Air-to-Water Heat Pump GAHP-AR.

Image: Heating GAHP-AR Absorption Thermodynamic Cycle

The multi-gas burner (D) is used to heat the absorbent-refrigerant solution causing the two components to separate by evaporation of the refrigerant in the distillation column (C). The burner-distillation column complex is called a generator and in absorption machines replaces the compressor typical of vapor compression equipment.

The hot refrigerant vapor leaving the generator, passing through the rectifier (B), separates from the last parts of water present and enters the shell-and-tube heat exchanger (L), which in the winter season assumes the role of condenser-absorber of the machine.

In this part of the circuit, the heat exchanger acts as a condenser for the refrigerant, which gives up its latent heat of condensation to the water in the heating system. This state transition of the refrigerant thus constitutes the first useful effect of the machine. The refrigerant leaving the condenser section passes through a first lamination section, a "tube-to-tube" heat exchanger (G), and a second lamination section where it is gradually, through successive decreases in pressure and temperature, brought to ideal conditions to change state again by passing to the gas phase. In the finned coil (A) in fact, the refrigerant, taking heat from the air in the external environment, evaporates. In this part of the circuit, the heat pump imports a portion of aerothermal renewable energy into the cycle.

It is interesting to know that the refrigerant used by GAHP heat pumps in the finned coil can evaporate at atmospheric pressure even at a temperature of -27.4° F. This thermodynamic characteristic of the refrigerant makes it possible to draw renewable energy from the air even when the temperature of the air reaches strongly negative values, and thus makes it possible not to need back up boilers. The ammonia evaporated in the finned coil, after overheating in the "tube-to-tube" exchanger (G) enters the pre-absorber (F) where meeting with the nebulized absorbent (water) gives rise to the absorption reaction proper.

Absorption is an exothermic chemical reaction that needs to have the emitted heat energy removed in order to evolve. In the pre-absorber, this energy is partially used to pre-heat the water-ammonia solution about to re-enter the generator. To complete the absorption reaction, the solution is sent back to the shell and tube heat exchanger (L). At this stage of the cycle, the exchanger acts as an absorber and allows a considerable amount of thermal energy to be transferred to the heat transfer fluid of the thermal system, which is the second useful effect of the machine. The ammonia-water solution exiting the heat exchanger (L) is sent by the solution pump (E) back to the generator, passing again through the pre-absorber (F) and the rectifier (B) where it pre-heats by recovering heat from the cycle itself. The refrigeration cycle now described then begins again in the generator. Position (H) in the drawing represents the heat pump cycle reversing valve, consisting of a mechanical organ through which the flow of refrigerant in the circuit is diverted. This operation makes it possible to seasonally reverse the mode of operation and produce hot water in the winter season and chilled water in the summer season. Position (K), on the other hand, shows the defrosting valve, which allows, if necessary, rapid defrosting of the finned coil, without the need to reverse the refrigeration cycle or to activate electrical auxiliaries. This is because, as can be seen from the diagram, only one of the two energy inputs to the evaporator is diverted to the coil, and that is in this case hot ammonia vapor. This makes it possible to ensure rapid (in times on the order of 180 seconds) ice removal and at the same time maintain 50 percent power to the heating circuit, without appreciably altering the efficiency of the machine.

NOTES:

- Always follow the local or national regulations in force for the specific case under consideration.

- In the spirit of continuous improvement that has always guided the company philosophy any contribution or suggestion aimed at improving this document is welcome and can be directed to our specialists.

- All words that appear underlined are links to other content, which will therefore not be available if the document is printed.

- The present contents are in the nature of technical guidance. They are therefore not intended as executive indications, and under no circumstances can Robur Corporation be held responsible if these indications are adopted without the prior favorable opinion of a licensed designer, on whom the responsibility for design choices falls by law.

Comments