K18 Simplygas gas absorption heat pump

Modulating condensing gas/LPG and aerothermal renewable energy absorption heat pump.

High-efficiency heating and domestic hot water production with the 2-pipe system (alternating heating and buffer tank domestic hot water production).

Benefits

- Maximum efficiency with no electricity use

Gas + Renewable energies: up to 169% efficiency

A rational use of energy brings the best results in terms of performance. By using heat that is present in large quantities in nature – in this case, in the air – and a primary source such as natural gas, K18 absorption heat pumps deliver high performance with up to 169% efficiency. - High-efficiency heating and hot water no matter what, even at -25 °C

65 °C for heating

70 °C for domestic hot water

Thanks to the special features of the thermodynamic cycle, the performance of K18 is barely affected by external climatic conditions. This results in hot water production up to 70 °C even in extremely cold climates. They’ve also got an antifreeze function which works without the use of heating elements. - Real savings

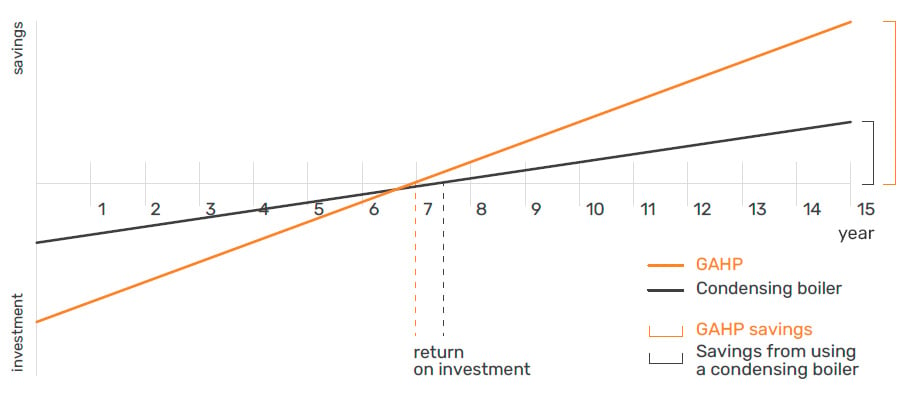

-50% heating costs

The achievable economic result of the high thermal efficiency of K18 over the whole lifetime of the system highlights the cost-effectiveness compared to condensing boiler technology.

The return on investment will be even quicker if the benefits and incentives available for technology focused on using renewable energy (like the K18) are taken advantage of.

- No increase in electrical power

Easy to install and can be integrated into any high- or low-temperature system. No chimney necessary, and no increase in electricity used. - Only natural refrigerants

F-Gas free and Zero GWP

By using a natural refrigerant (ammonia), which is not subject to restrictions and declaration requirements, K18 has a near-zero impact on global warming and solves the problem of HFCs. It is also exempt from F-Gas regulations.

The European Commission Joint Research Centre, in a study on different air conditioning technologies, has highlighted that the gas heat pump is the technology with the lowest overall environmental impact in terms of emissions harmful to human health (NOx, PM, VOC, COx).